knitting

Société Choletaise de Fabrication is equipped with a range of knitting machines for the manufacture of knitted fabrics and tubular knitted laces.

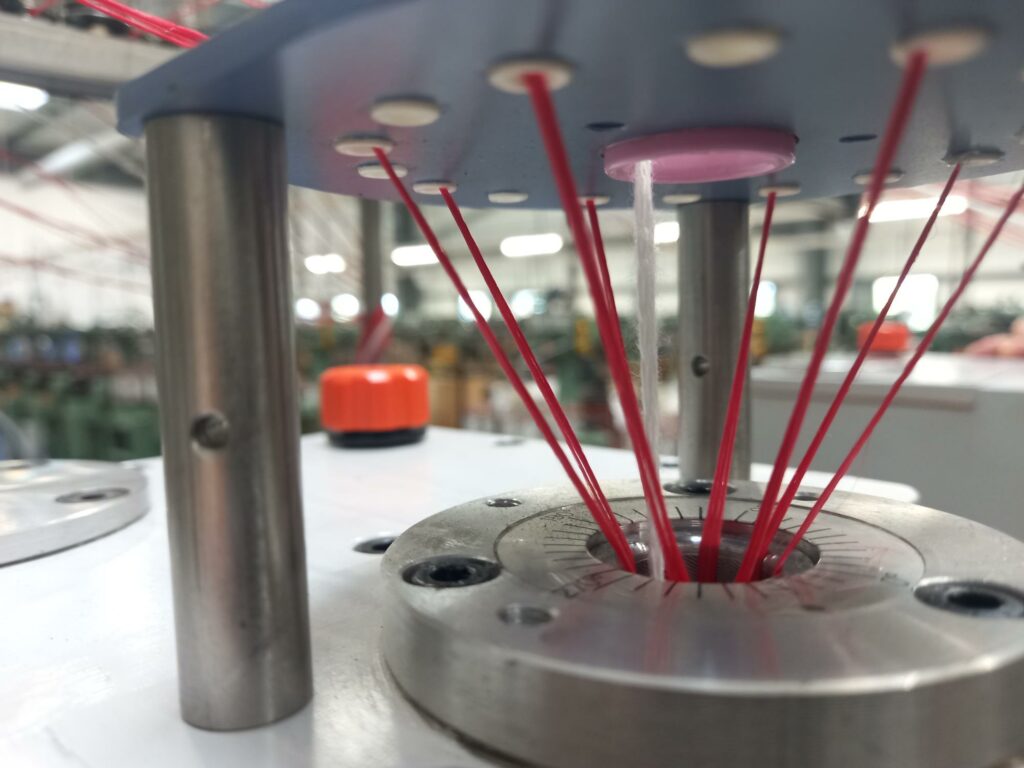

Circular knitting machines

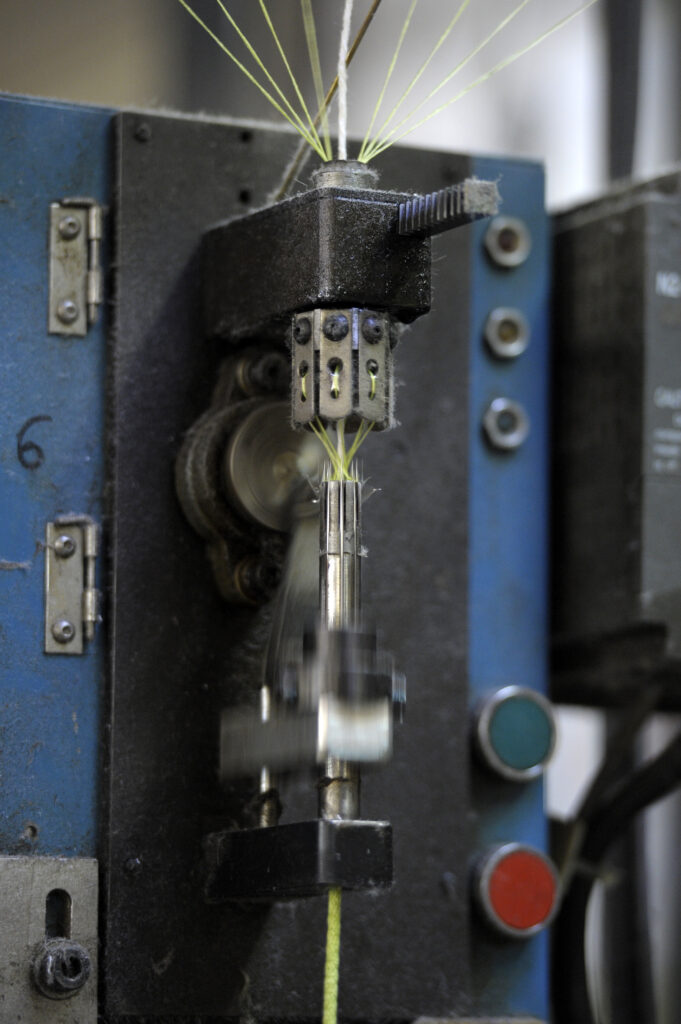

Circular knitting machines, commonly known as tubular knitting machines, are used to make three types of stitch, the diameter and fineness of which vary according to the gauge used.

The greater the number of needles, the greater the diameter. The finer the yarn used, the finer the knitted stitch.

Knitwear can be plain, patterned or mottled.

The speed with which knitted products are produced means that we can achieve high production capacity within short lead times.

Products

SCF’s three types of industrial knitting machines manufacture a variety of products:

- flat tubular cords with no core* and a relatively tight mesh. Their diameters are adjustable, ranging from a few millimetres to a few centimetres.

- These knitted fabrics are used to make laces, hood cords, packaging, jewellery, etc.

- “Lambes” cords, round tubular cords with or without a core and adjustable diameters. These cords are flexible, with a more or less tight mesh. These products are regularly used for swimwear applications (swimming costume cords).

- “Semel” cords, round tubular cords with or without a core, more or less flexible. These knitted fabrics can be used as swimwear ties, sweater cords, bag fastenings for leather goods, etc.

- square cords with one or more visible cores.

Core: cord(s) or strand inserted into the knitted (or braided) cord. The product is knitted (or braided) around the core, which gives it volume and bulk.