mechanical bobbin lace machine

With a fleet of 70 mechanical bobbin lace looms, Société Choletaise de Fabrication is one of the last lacemakers and manufacturers in France to create and manufacture lace, ribbon lace and elastic lace.

History of SCF’s mechanical bobbin lace looms

The adventure began in 2016, with the repatriation of the lace looms from Le Puy en Velay.

These Jacquard braiding looms were added to the fleet of slow-revolution wooden braiding looms acquired 3 years earlier.

Lace is a light, delicate textile made by interlacing threads to form complex patterns. For centuries, lace was made by hand, using spindles and shuttles to braid the threads.

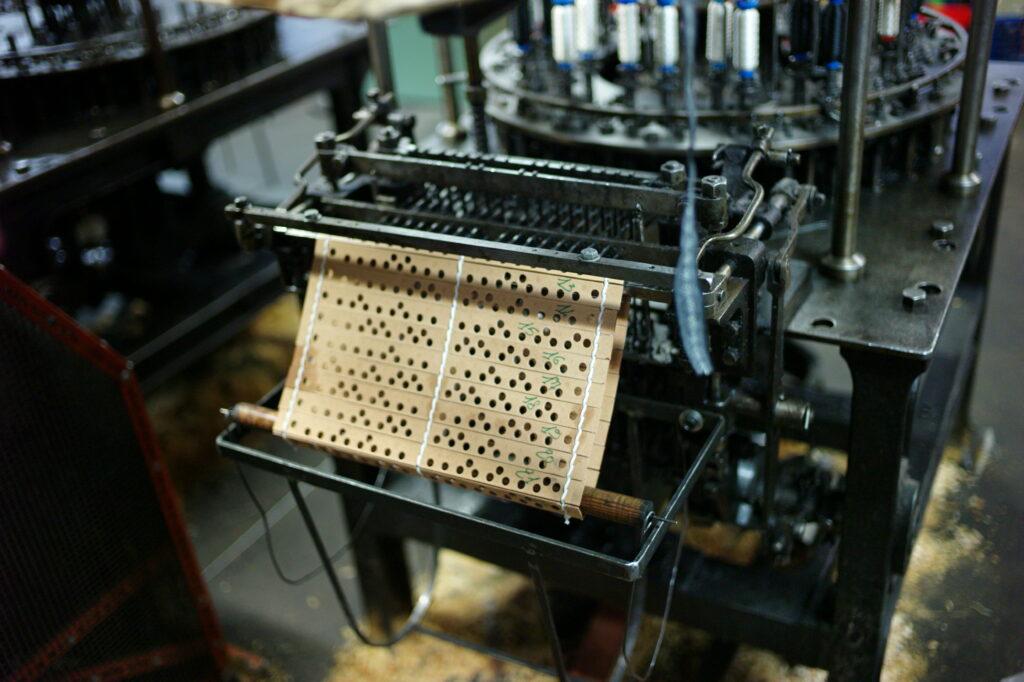

The mechanical bobbin lace loom was invented at the end of the 18th century. This new loom could weave faster and more evenly than traditional manual methods. Wooden perforated cards, called “jacquards”, were used to guide the movements of the bobbins, enabling manufacturers to produce more complex patterns more quickly than ever before. These jacquards are the transcription of the lace ribbon pattern; the translation of the design by the lacemaker.

This unique know-how and its manufacturing methods have been the subject of extensive initial training for our lacemakers, which continues to this day.

Indeed, former lace-makers from Le Puy continue to pass on their knowledge of lace design, loom restoration and the adjustment and understanding of old jacquards to our lace-makers.

So our lacemakers can design new lace motifs, transcribe the designs by punching the wooden cards and finally assemble and adjust the lace loom with the spools of thread that will weave the lace ribbon.

Production

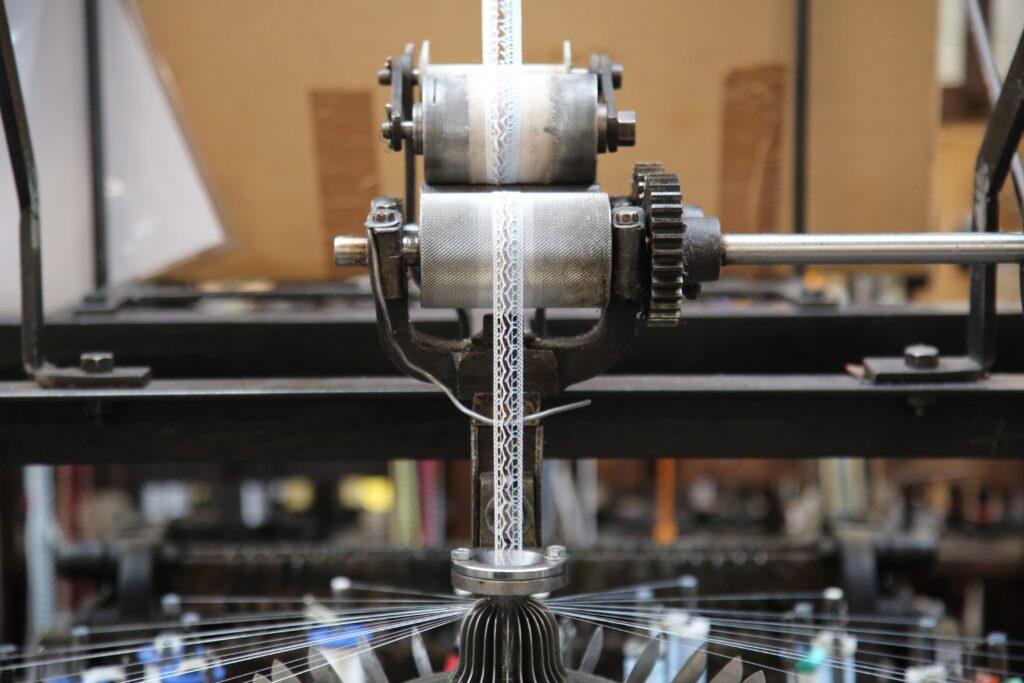

SCF creates high-quality, exclusive and refined products using delicate materials with fine titling and a meticulous braiding technique.

With a production rate of around 2.5 metres per hour, SCF offers its customers short delivery times and large-scale production thanks to its ability to start up several identical jacquard lace looms on the 70 machines available.

With over 2,000 jacquards available, lace collections can be modified in terms of material, colour and pattern. It is entirely possible to transform a lace so that it corresponds in every respect to our customers’ expectations.

Lace products

The laces and lace ribbons, also known as in-between laces, produced on these Jacquard looms are used to make or insert garments, lingerie, swimwear, fashion accessories and household linen.

The mechanical Jacquard bobbin lace loom can produce a wide variety of designs, including floral, geometric and abstract motifs.

There are 4 types of laces:

- ribbon lace, also known as “entre deux” lace: lace with parallel edges, perhaps embellished with 2 seam feet

- lace without a sewing foot

- lace with a single sewing foot, also known as lace

- elastic lace: ribbon lace of the entre-deux type, lace without a seam foot, or lace with a seam foot.

The grain of the lace will depend on the material and thread count used.

Thanks to its slow braiding, lace supports fine threads such as mercerised cottons and organic cottons, linen and hemp, recycled polyester and textured polyester, polyamides, metallic threads such as Lurex, etc.

To find out more about the history of lace looms, go to www.persee.fr